Control systems like high-vibration motor system are of great value since it helps machines work properly and smoothly. Do you ever wonder if these systems are reliable? Reliability has been a superpower that helps these systems function smoothly. High-vibration motor control systems and why reliability is essential to ensure they all work properly.

Understanding reliability in high-vibration motor control systems is similar to knowledge of how to maintain your favorite toy in good, working condition. (Just see if you would like your toy to stop working every time you played with it.) Which is why reliability can be considered so important — you need the motor control systems to keep right on running, even when they’re really beat up.

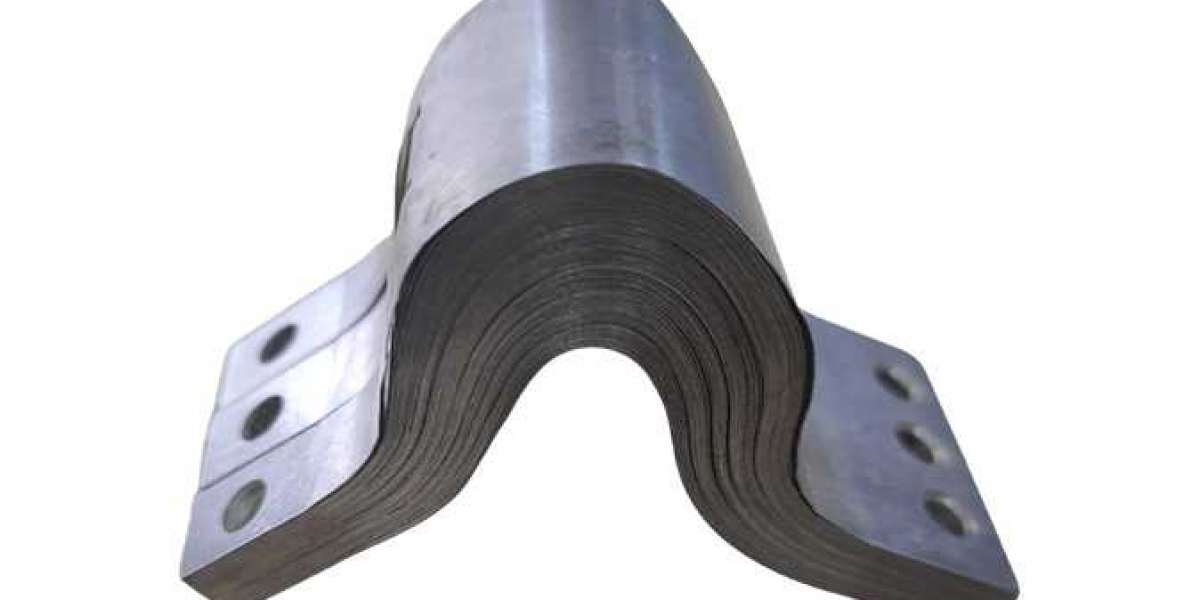

Ok, now onto laminated copper shunts. And these copper shunts act like the muscles in a motor control system — they ease the flow of electricity, making the chip more efficient. But how are they in hard places that induce a lot of vibration? That’s where we test reliability.

It is about how laminated copper shunts behave, or not, in harsh environments, just as you would check at the end of the day if your shoes are still comfy, after running all day. Copper shunts must be robust and stout in high-vibration motor control systems to keep up with the shuddering. This is why testing them is important, to ensure they can take the heat.

The influence of vibration on reliability of motor control systems is similar to that of rocky roads for automobiles. Just as a car can get jostled on a bumpy road, if the motor control systems aren’t reliable enough to cope with the vibrations, they can have issues. Which is why it is crucial to make sure that the copper shunts in these systems are up to these and other tasks.

Some of the small busbar important considerations to keep in mind while determining reliability of laminated copper shunts include its durability, its flexibility and its conductivity. In other words, durability is the ability of the copper shunts to withstand vibration without breaking or wearing out. You need them to be flexible, so that they can rotate to different positions. Conductivity Ensuring electricity can flow easily through the copper shunts to drive the motor 600 amp bus bar control systems effectively.

Ensuring the longevity of copper shunts in motor control systems is like maintaining your favorite toy for extended playtime. With copper shunts, we can test and inspect the motor control systems, and be confident that they’ll remain operational, even in vibratey locations.

Reliability checking is vital for high-vibration interrogation motor control systems to perform properly. We can 400a busbar ensure these systems last and remain sound by understanding how laminated copper shunts perform and considering factors such as longevity, flexibility and conductivity. So when you witness a high-vibration motor control system in operation, you will find new respect for the value of reliable performance!