Carbon fiber is known for its excellent stiffness-to-weight ratio, ensuring minimal weight without compromising strength. With their high strength and low weight, carbon fiber foil sets are ideal for demanding industries such as aerospace, automotive, and sports equipment manufacturing. Whether it's for creating lightweight structures, improving fuel efficiency, or enhancing performance, carbon fiber foil sets are a reliable choice.

Properties

Carbon fiber foil sets offer a range of exceptional properties that make them a popular choice for various applications. From their lightweight nature to high strength and corrosion resistance, carbon fiber foils possess unique characteristics that set them apart from other materials.

Lightweight

Carbon fiber foil sets are extremely lightweight, making them ideal for applications where weight is a critical factor. The use of carbon fibers, which are incredibly thin and light, allows for the creation of lightweight foils that are easy to handle and install.

High Strength

High strength is another prominent feature of carbon fiber foil sets. Despite their lightweight nature, these foils boast exceptional strength and durability, making them suitable for demanding applications that require robust materials.

Corrosion Resistance

Carbon fiber foils exhibit corrosion resistance, making them well-suited for outdoor and marine applications. Their ability to withstand environmental factors such as moisture and saltwater ensures long-term durability and reliability in diverse settings.

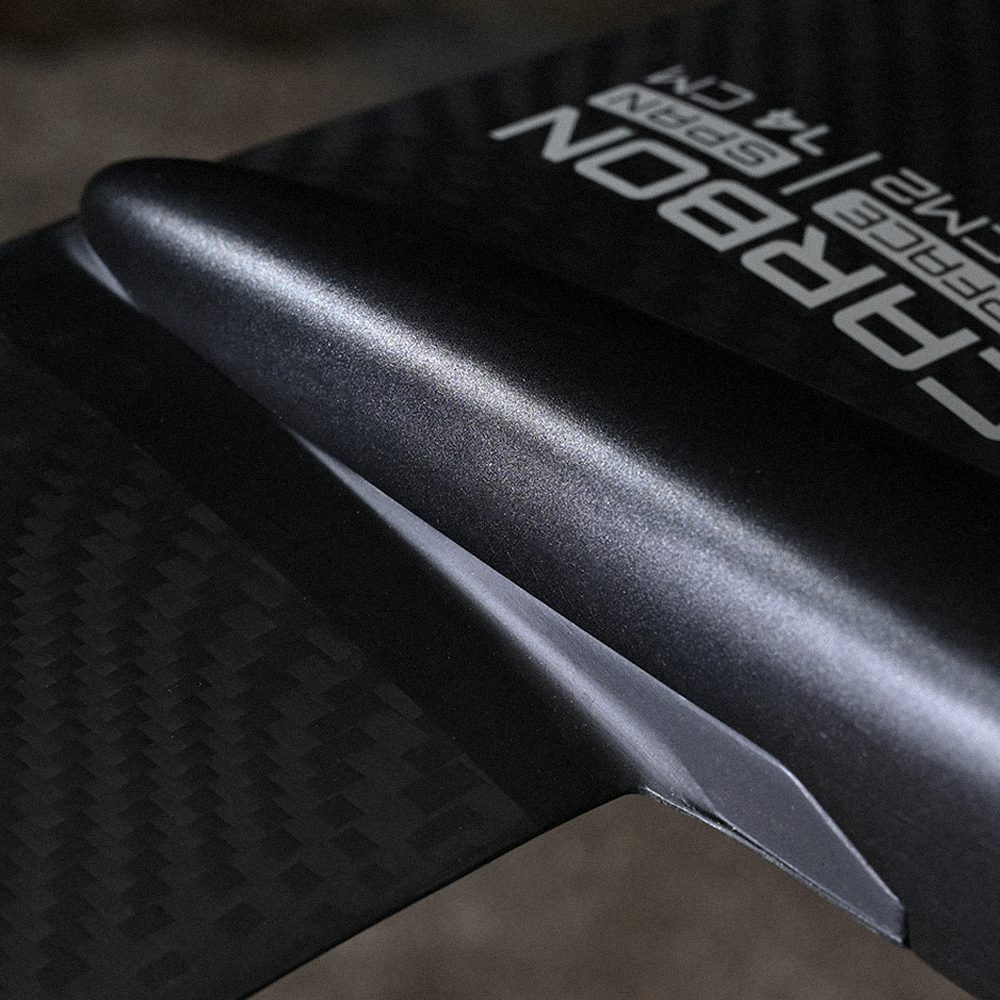

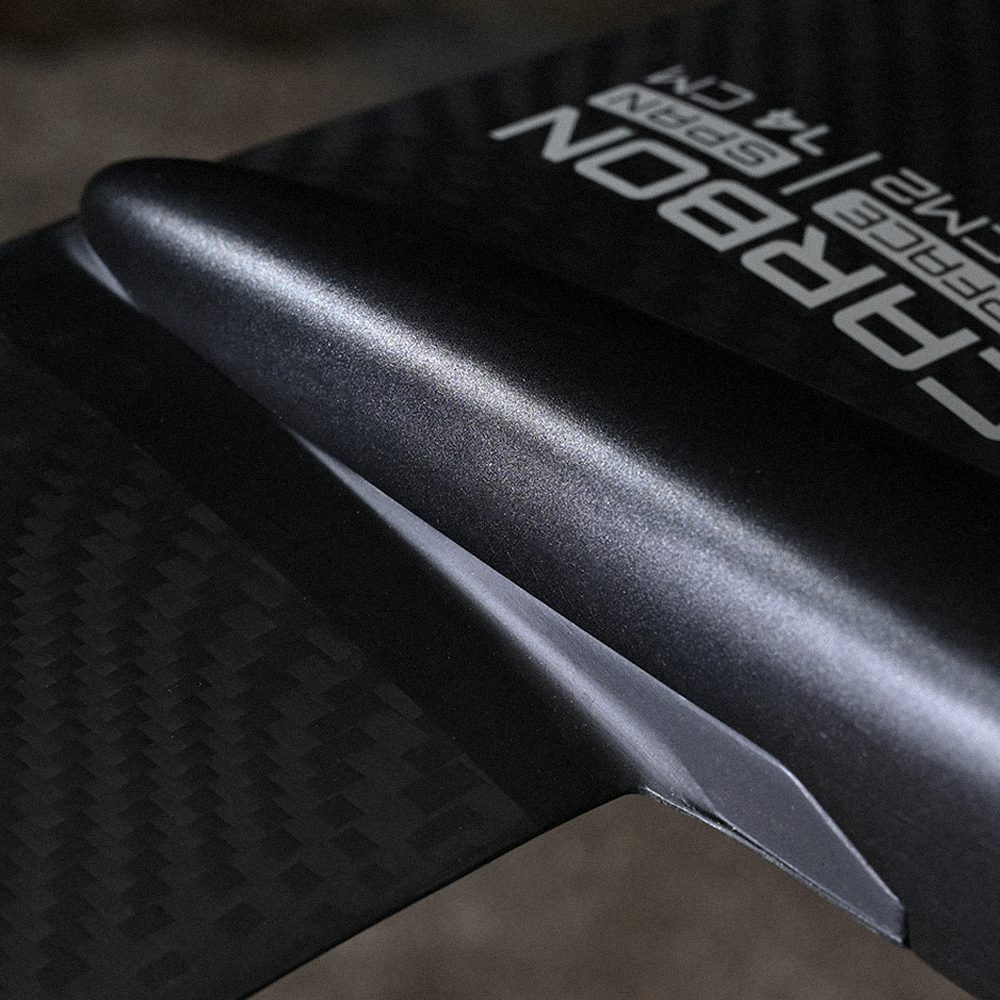

Credit: https://pakaafoilhawaii.com

Manufacturing Process

The manufacturing process of carbon fiber foil sets involves the weaving of carbon fiber strands into a cloth, which is then combined with resin to create the foil. The material is then cured to achieve its final form, resulting in a lightweight and strong product used in various industries.

Raw Material Selection

Carbon Fiber Foil sets start with meticulous raw material selection, ensuring quality and durability. Manufacturers choose carbon fibers based on strength and lightweight properties.

Formation Of Carbon Fiber Foil

The formation process involves precise layering of carbon fibers in specific patterns. Resin infusion follows to create a solid composite structure.

Benefits

Carbon fiber foil sets offer a range of advantages that make them a popular choice among enthusiasts and professionals alike. The benefits of using carbon fiber foil sets can be summarized into two key areas: Improved Performance and Enhanced Durability.

Improved Performance

- Lightweight design enhances maneuverability and speed.

- Superior strength-to-weight ratio improves overall performance.

- Enhanced stability allows for better control and precision.

Enhanced Durability

- Resistant to corrosion for long-lasting use in various conditions.

- Minimal maintenance required due to durable construction.

- High fatigue resistance ensures longevity and consistent performance.

Credit: forcekiteandwake.com

Uses Across Industries

Carbon fiber foil sets are versatile and find applications in various industries. Their lightweight yet strong properties make them a preferred choice across different sectors. Let’s explore how carbon fiber foil sets are used in the aerospace industry, automotive applications, and sports equipment.

Aerospace Industry

Carbon fiber foil sets are extensively used in the aerospace industry for constructing aircraft structures due to their exceptional strength-to-weight ratio. The material’s high stiffness and resistance to fatigue make it ideal for building critical components such as wings, fuselage sections, and tail sections.

Automotive Applications

In the automotive sector, carbon fiber foil sets are employed to manufacture lightweight body panels, aerodynamic components, and chassis elements. These sets contribute to reducing vehicle weight, enhancing fuel efficiency, and improving overall performance. Additionally, they are utilized in luxury car interiors for their aesthetic appeal and durability.

Sports Equipment

Carbon fiber foil sets are integral in the production of high-performance sports equipment such as tennis rackets, golf clubs, bicycles, and fishing rods. The material’s strength and flexibility ensure that the equipment is robust while remaining lightweight. This makes carbon fiber foil sets an essential choice for professional athletes and amateur sports enthusiasts alike.

Challenges

Despite the numerous benefits and applications of carbon fiber foil sets, they do come with their fair share of challenges. Here, we explore two key challenges in utilizing these cutting-edge materials: cost constraints and complex repair processes.

Cost Constraints

One of the primary hurdles in adopting carbon fiber foil sets is the issue of cost. While carbon fiber offers exceptional strength-to-weight ratio and durability, its production and manufacturing processes can be expensive. Due to the intricate fabrication techniques and high-quality materials involved, carbon fiber products tend to be priced at a premium.

However, it is important to consider the long-term advantages that carbon fiber foil sets offer. Despite the initial investment, their superior performance can often outweigh the higher upfront cost. The lightweight nature of carbon fiber helps reduce fuel consumption and increase overall efficiency, making it an ideal choice for industries such as aerospace and automotive.

Complex Repair Processes

Another challenge related to carbon fiber foil sets lies in the complexity of repair processes. Unlike traditional materials, such as steel or aluminum, carbon fiber requires specialized techniques and expertise to repair effectively.

Due to the layered structure and resin matrix of carbon fiber, any damage or structural issues need to be addressed with precision and care. Repairing carbon fiber foil sets often involves intricate procedures like vacuum bagging, epoxy infusion, or even patching individual fibers. These processes can be time-consuming and require skilled technicians.

When encountering damage, it is crucial to consult a professional with experience in carbon fiber repair to ensure optimal results. Attempting DIY repairs or using inexperienced technicians can potentially lead to subpar repairs, compromising the structural integrity of the carbon fiber foil sets.

Credit: www.patrikinternational.com

Future Applications

Future Applications:

Advancements In Technology

Carbon fiber foil sets are at the forefront of groundbreaking advancements.

These sets incorporate cutting-edge technology for enhanced performance.

Materials like graphene-reinforced fibers further push the boundaries.

Potential In Emerging Industries

Carbon fiber foil sets hold immense potential in diverse sectors.

Their lightweight and durable nature make them ideal for aerospace applications.

In the automotive sector, these sets reduce fuel consumption and enhance efficiency.

Sports equipment manufacturers are also tapping into this technology for advanced products.

Conclusion

Carbon fiber foil sets offer lightweight, durable, and high-performance solutions for various applications. Whether in the aerospace, automotive, or sports industry, the versatility and strength of carbon fiber foils make them an ideal choice. With a commitment to innovation and quality, these foil sets are revolutionizing industries and setting new standards.

Carbon fiber is known for its excellent stiffness-to-weight ratio, ensuring minimal weight without compromising strength. With their high strength and low weight, carbon fiber foil sets are ideal for demanding industries such as aerospace, automotive, and sports equipment manufacturing. Whether it's for creating lightweight structures, improving fuel efficiency, or enhancing performance, carbon fiber foil sets are a reliable choice.

Properties

Carbon fiber foil sets offer a range of exceptional properties that make them a popular choice for various applications. From their lightweight nature to high strength and corrosion resistance, carbon fiber foils possess unique characteristics that set them apart from other materials.

Lightweight

Carbon fiber foil sets are extremely lightweight, making them ideal for applications where weight is a critical factor. The use of carbon fibers, which are incredibly thin and light, allows for the creation of lightweight foils that are easy to handle and install.

High Strength

High strength is another prominent feature of carbon fiber foil sets. Despite their lightweight nature, these foils boast exceptional strength and durability, making them suitable for demanding applications that require robust materials.

Corrosion Resistance

Carbon fiber foils exhibit corrosion resistance, making them well-suited for outdoor and marine applications. Their ability to withstand environmental factors such as moisture and saltwater ensures long-term durability and reliability in diverse settings.

Credit: www.patrikinternational.com

Manufacturing Process

The manufacturing process of carbon fiber foil sets involves the weaving of carbon fiber strands into a cloth, which is then combined with resin to create the foil. The material is then cured to achieve its final form, resulting in a lightweight and strong product used in various industries.

Raw Material Selection

Carbon Fiber Foil sets start with meticulous raw material selection, ensuring quality and durability. Manufacturers choose carbon fibers based on strength and lightweight properties.

Formation Of Carbon Fiber Foil

The formation process involves precise layering of carbon fibers in specific patterns. Resin infusion follows to create a solid composite structure.

Benefits

Carbon fiber foil sets offer a range of advantages that make them a popular choice among enthusiasts and professionals alike. The benefits of using carbon fiber foil sets can be summarized into two key areas: Improved Performance and Enhanced Durability.

Improved Performance

- Lightweight design enhances maneuverability and speed.

- Superior strength-to-weight ratio improves overall performance.

- Enhanced stability allows for better control and precision.

Enhanced Durability

- Resistant to corrosion for long-lasting use in various conditions.

- Minimal maintenance required due to durable construction.

- High fatigue resistance ensures longevity and consistent performance.

Credit: forcekiteandwake.com

Uses Across Industries

Carbon fiber foil sets are versatile and find applications in various industries. Their lightweight yet strong properties make them a preferred choice across different sectors. Let’s explore how carbon fiber foil sets are used in the aerospace industry, automotive applications, and sports equipment.

Aerospace Industry

Carbon fiber foil sets are extensively used in the aerospace industry for constructing aircraft structures due to their exceptional strength-to-weight ratio. The material’s high stiffness and resistance to fatigue make it ideal for building critical components such as wings, fuselage sections, and tail sections.

Automotive Applications

In the automotive sector, carbon fiber foil sets are employed to manufacture lightweight body panels, aerodynamic components, and chassis elements. These sets contribute to reducing vehicle weight, enhancing fuel efficiency, and improving overall performance. Additionally, they are utilized in luxury car interiors for their aesthetic appeal and durability.

Sports Equipment

Carbon fiber foil sets are integral in the production of high-performance sports equipment such as tennis rackets, golf clubs, bicycles, and fishing rods. The material’s strength and flexibility ensure that the equipment is robust while remaining lightweight. This makes carbon fiber foil sets an essential choice for professional athletes and amateur sports enthusiasts alike.

Challenges

Despite the numerous benefits and applications of carbon fiber foil sets, they do come with their fair share of challenges. Here, we explore two key challenges in utilizing these cutting-edge materials: cost constraints and complex repair processes.

Cost Constraints

One of the primary hurdles in adopting carbon fiber foil sets is the issue of cost. While carbon fiber offers exceptional strength-to-weight ratio and durability, its production and manufacturing processes can be expensive. Due to the intricate fabrication techniques and high-quality materials involved, carbon fiber products tend to be priced at a premium.

However, it is important to consider the long-term advantages that carbon fiber foil sets offer. Despite the initial investment, their superior performance can often outweigh the higher upfront cost. The lightweight nature of carbon fiber helps reduce fuel consumption and increase overall efficiency, making it an ideal choice for industries such as aerospace and automotive.

Complex Repair Processes

Another challenge related to carbon fiber foil sets lies in the complexity of repair processes. Unlike traditional materials, such as steel or aluminum, carbon fiber requires specialized techniques and expertise to repair effectively.

Due to the layered structure and resin matrix of carbon fiber, any damage or structural issues need to be addressed with precision and care. Repairing carbon fiber foil sets often involves intricate procedures like vacuum bagging, epoxy infusion, or even patching individual fibers. These processes can be time-consuming and require skilled technicians.

When encountering damage, it is crucial to consult a professional with experience in carbon fiber repair to ensure optimal results. Attempting DIY repairs or using inexperienced technicians can potentially lead to subpar repairs, compromising the structural integrity of the carbon fiber foil sets.

Credit: www.patrikinternational.com

Future Applications

Future Applications:

Advancements In Technology

Carbon fiber foil sets are at the forefront of groundbreaking advancements.

These sets incorporate cutting-edge technology for enhanced performance.

Materials like graphene-reinforced fibers further push the boundaries.

Potential In Emerging Industries

Carbon fiber foil sets hold immense potential in diverse sectors.

Their lightweight and durable nature make them ideal for aerospace applications.

In the automotive sector, these sets reduce fuel consumption and enhance efficiency.

Sports equipment manufacturers are also tapping into this technology for advanced products.

Conclusion

Carbon fiber foil sets offer lightweight, durable, and high-performance solutions for various applications. Whether in the aerospace, automotive, or sports industry, the versatility and strength of carbon fiber foils make them an ideal choice. With a commitment to innovation and quality, these foil sets are revolutionizing industries and setting new standards.