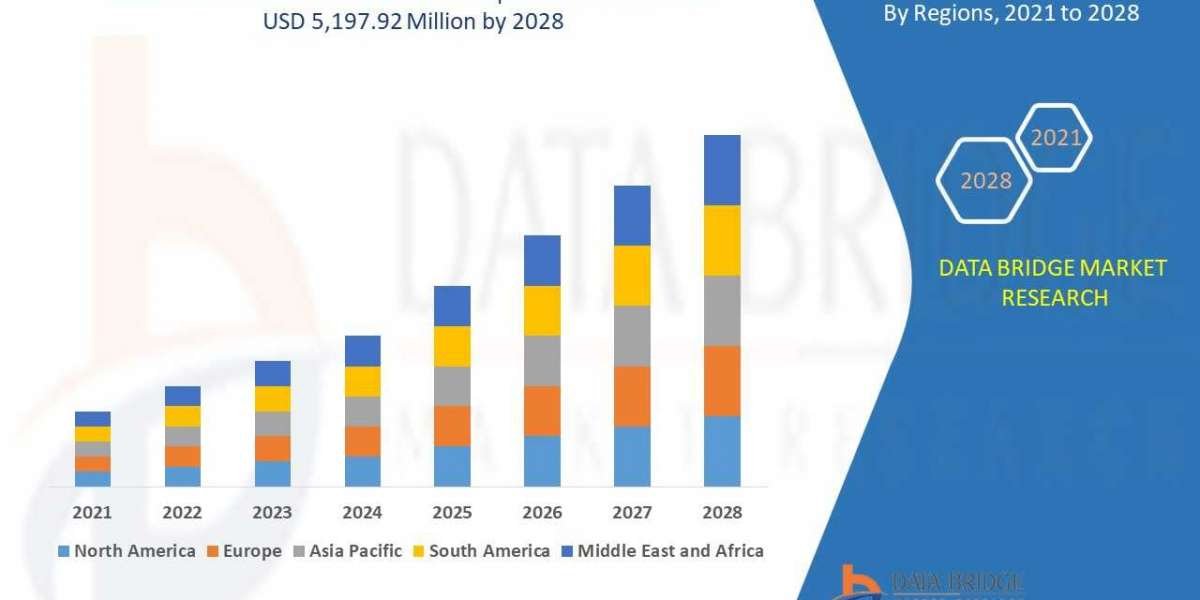

The Automotive Wiring Harness Market Size is a pivotal sector within the automotive industry, facilitating the seamless flow of electrical signals and power throughout vehicles. As vehicles become increasingly complex, with advanced electronics and connectivity features, the demand for sophisticated wiring harnesses grows. The global automotive wiring harness market is expected to witness a robust growth rate, with a projected CAGR of 6% from 2024 to 2032. This article delves into the market's key benefits, developments, driving and restraining factors, and offers a comprehensive analysis of its current and future landscape.

Key Benefits of Automotive Wiring Harnesses

Improved Electrical Efficiency: Automotive wiring harnesses streamline the electrical systems within vehicles, enhancing overall efficiency. By ensuring that electrical signals and power are distributed reliably and with minimal loss, they contribute to the optimal functioning of various vehicle components.

Enhanced Safety: Wiring harnesses are designed with safety in mind. They reduce the risk of electrical short circuits and fires by incorporating protective insulation and fail-safes. This enhances the overall safety of vehicles, safeguarding both passengers and the vehicle itself.

Reduced Vehicle Weight: Modern automotive wiring harnesses are designed to be lightweight yet durable. By using advanced materials and optimized designs, these harnesses contribute to reducing the overall weight of the vehicle, which in turn improves fuel efficiency and performance.

Cost-Effectiveness: While the initial investment in high-quality wiring harnesses may be significant, their durability and reliability lead to lower maintenance and repair costs over the vehicle's lifespan. This makes them a cost-effective solution for automotive manufacturers.

Key Industry Developments

Technological Advancements: The automotive industry is witnessing rapid technological advancements, including the integration of electric and autonomous vehicles. This has led to the development of more sophisticated wiring harnesses capable of handling complex electrical systems and communication networks.

Growing Electric Vehicle (EV) Market: The rise in electric vehicle adoption is significantly influencing the automotive wiring harness market. EVs require specialized wiring harnesses to manage high-voltage systems and battery management, driving innovation in harness design and materials.

Smart and Connected Vehicles: The trend towards smart and connected vehicles is leading to the incorporation of advanced features such as infotainment systems, advanced driver assistance systems (ADAS), and in-car networking. These features necessitate the development of wiring harnesses that can support high data transmission rates and increased functionality.

Driving Factors

Increasing Vehicle Electrification: The growing emphasis on electrification and the integration of advanced electronic components in vehicles are major driving factors for the automotive wiring harness market. As vehicles incorporate more electrical and electronic systems, the demand for efficient and reliable wiring harnesses rises.

Regulatory Standards: Stringent safety and emission regulations are pushing automotive manufacturers to adopt high-quality wiring harnesses that meet industry standards. Compliance with these regulations ensures vehicle safety, reliability, and performance.

Rising Vehicle Production: The global increase in vehicle production, driven by rising consumer demand and economic growth, is fueling the need for automotive wiring harnesses. Higher production volumes translate to increased demand for these critical components.

Restraining Factors

High Raw Material Costs: The cost of raw materials used in wiring harnesses, such as copper and polymers, can be volatile. Fluctuations in material costs can impact the overall cost of production and affect profit margins for manufacturers.

Complex Manufacturing Processes: The manufacturing of automotive wiring harnesses involves complex processes and requires precise engineering. Challenges in maintaining consistent quality and performance can pose constraints for manufacturers.

Competition from Alternative Technologies: Emerging technologies and alternative solutions, such as wireless power transmission and advanced connector systems, may present competition to traditional wiring harnesses. The industry must continuously innovate to stay ahead of these technological advancements.

Market Segmentation

By Application:

- Interior Wiring: Includes wiring for lighting, infotainment systems, and climate control.

- Exterior Wiring: Covers wiring for lighting, sensors, and power distribution.

- Powertrain Wiring: Involves wiring for engine management, transmission control, and battery systems.

By Vehicle Type:

- Passenger Vehicles: Includes cars, SUVs, and hatchbacks.

- Commercial Vehicles: Covers trucks, buses, and vans.

- Electric Vehicles: Focuses on electric and hybrid vehicles.

By Region:

- North America: Includes the United States, Canada, and Mexico.

- Europe: Covers Western and Eastern Europe.

- Asia-Pacific: Includes China, Japan, South Korea, and India.

- Rest of the World: Includes Latin America, the Middle East, and Africa.

Market Outlook

The automotive wiring harness market is poised for significant growth, driven by the increasing complexity of vehicles and advancements in automotive technology. The forecast period from 2024 to 2032 presents opportunities for market expansion, with a projected CAGR of 6%. Key factors contributing to this growth include rising vehicle production, technological advancements, and the growing emphasis on electric and connected vehicles.

Trends

Integration of Advanced Materials: The use of advanced materials, such as lightweight composites and high-temperature resistant polymers, is a key trend in wiring harness development. These materials enhance the performance and durability of harnesses.

Focus on Sustainability: The automotive industry is increasingly focusing on sustainability, leading to the development of eco-friendly wiring harnesses made from recyclable and sustainable materials.

Digitalization and Automation: The adoption of digital technologies and automation in the manufacturing process is improving the efficiency and precision of wiring harness production.

Industry Segmentation

The automotive wiring harness industry is segmented based on application, vehicle type, and region. Each segment presents unique opportunities and challenges, influencing market dynamics and growth potential.

Regional Analysis/Insights

North America: The region is a major market for automotive wiring harnesses due to the presence of leading automotive manufacturers and technological advancements. The demand for high-quality wiring harnesses is driven by the growing emphasis on safety and connectivity.

Europe: Europe is a key market for automotive wiring harnesses, with a focus on advanced vehicle technologies and stringent regulatory standards. The region is witnessing significant growth in electric and hybrid vehicles, driving the demand for specialized wiring harnesses.

Asia-Pacific: The Asia-Pacific region is experiencing rapid growth in vehicle production and adoption of new technologies. Countries like China and India are major contributors to the market, with increasing investments in automotive manufacturing and infrastructure.

Top Impacting Factors

Technological Innovation: Advances in automotive technology and the integration of new features drive the demand for innovative wiring harness solutions.

Regulatory Compliance: Adherence to safety and emission regulations influences the design and manufacturing of wiring harnesses.

Consumer Preferences: Shifts in consumer preferences towards electric and connected vehicles impact the demand for specific types of wiring harnesses.

Major Key Players

- Sumitomo Electric Industries Ltd.

- Furukawa Electric Co. Ltd.

- Yazaki Corporation

- Leoni AG

- Lear Corporation

Opportunities

Growth in Electric Vehicles: The expansion of the electric vehicle market presents opportunities for specialized wiring harnesses designed for high-voltage systems and battery management.

Technological Advancements: Innovations in wiring harness design and materials offer opportunities for manufacturers to develop advanced solutions that meet evolving industry requirements.

Emerging Markets: Growing automotive markets in regions such as Asia-Pacific provide opportunities for expansion and increased market share.

Challenges

Material Cost Fluctuations: Variability in raw material costs can impact production costs and profit margins.

Complex Manufacturing Requirements: Maintaining consistent quality and performance in complex manufacturing processes can be challenging.

Competitive Landscape: The presence of numerous players and emerging technologies adds to the competitive pressure in the market.

Scope

The automotive wiring harness market encompasses a wide range of applications and vehicle types, with significant growth potential driven by technological advancements, increasing vehicle production, and the rise of electric and connected vehicles. As the industry evolves, opportunities for innovation and market expansion will continue to shape the future of automotive wiring harnesses.

Read More Reports:

Global Vodka Market

Lithium-Ion Battery Market

United States Shrimp Market