The aerospace industry is always looking for ways to improve the efficiency, performance, and safety of their products. One of the latest innovations in this field is the use of electric inserts. Electric inserts are electrical components that are designed to improve the performance of aerospace systems while also reducing weight and increasing fuel efficiency. In this article, we will take a closer look at the aerospace electric inserts market and explore its growth potential, key trends, and future outlook.

The aerospace electric inserts market is a relatively new segment that is experiencing rapid growth due to the increasing demand for more efficient and eco-friendly aerospace systems. The market is driven by several factors such as the increasing demand for lightweight aircraft, the need for more electric aircraft systems, and the growing trend of electrification in the aerospace industry.

Types of Aerospace Electric Inserts:

There are several types of electric inserts that are used in the aerospace industry.

Some of the most common types include: Electrical Connectors: Electrical connectors are used to connect various electrical components in the aircraft. They are designed to be lightweight, durable, and able to withstand high temperatures and pressures.

Electrical Contacts: Electrical contacts are used to ensure proper electrical connections between different components in the aircraft. They are made of materials such as copper, silver, or gold, and are designed to be highly conductive and resistant to corrosion.

Electrical Contacts Springs: Electrical contact springs are used to maintain contact pressure between electrical contacts in the aircraft. They are designed to be highly resilient and to provide consistent pressure over long periods of time.

Electrical Circuit Breakers: Electrical circuit breakers are used to protect electrical circuits in the aircraft from overloads and short circuits. They are designed to be lightweight, compact, and reliable.

Applications of Aerospace Electric Inserts: Electric inserts are used in a wide range of aerospace applications.

Some of the most common applications include: Avionics: Avionics is the electronic systems used in aircraft to monitor and control various systems. Electric inserts are used in avionics to connect and protect electrical components, and to ensure proper functionality.

Electrical Power Systems: Electric inserts are used in the electrical power systems of aircraft to control and protect electrical circuits. They are also used to distribute power to various systems in the aircraft.

Lighting Systems: Electric inserts are used in the lighting systems of aircraft to connect and protect the various electrical components.

Communication Systems: Electric inserts are used in the communication systems of aircraft to connect and protect the various electronic components.

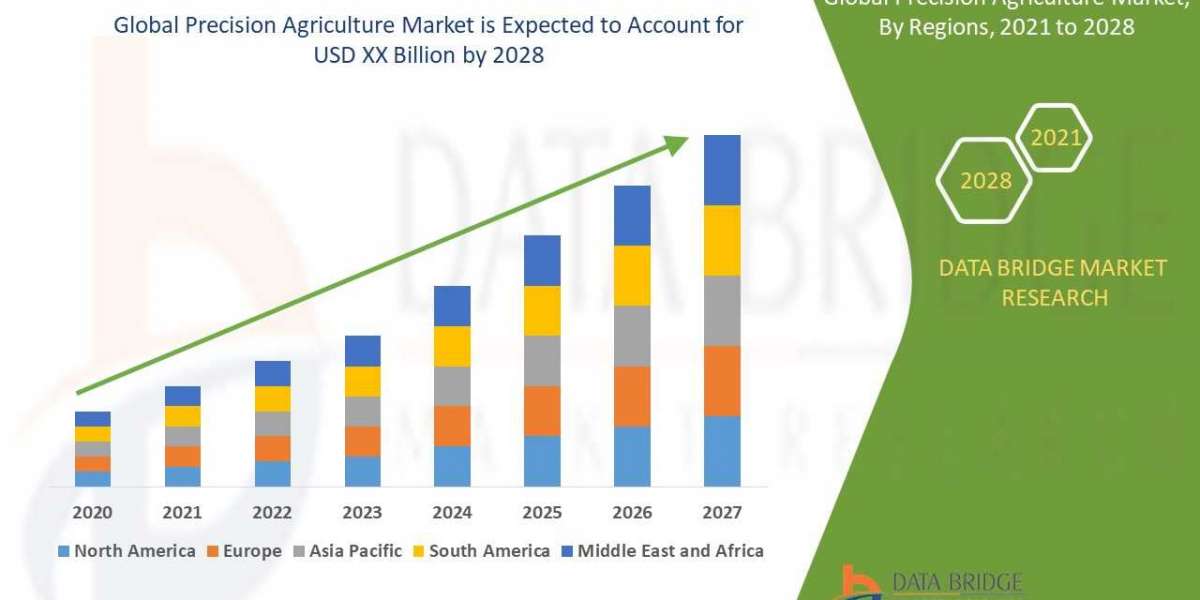

Regional Outlook: The aerospace electric inserts market is dominated by North America and Europe, due to the presence of major aerospace companies such as Boeing, Airbus, and Rolls-Royce. However, the market is expected to grow rapidly in the Asia-Pacific region, due to the increasing demand for air travel in the region and the growing investments in the aerospace industry.

The Middle East and Africa and Latin America regions are also expected to experience significant growth in the coming years, due to the increasing investments in the aerospace industry in these regions.