Welding is essential in many industries to create strong bonds between metals. Welding has long been a critical component of the construction, manufacturing, and automotive sectors. While traditional welding methods primarily focus on using heat to melt metal parts, another type of welding technology is gaining attention water welders. These machines combine water with welding technology to produce a cleaner, more efficient, and eco-friendly approach to welding.

This article will explore what water welders are, how they work, and the benefits they offer compared to conventional welding methods. By the end of this, you will have a clearer understanding of the value of water welders to industries.

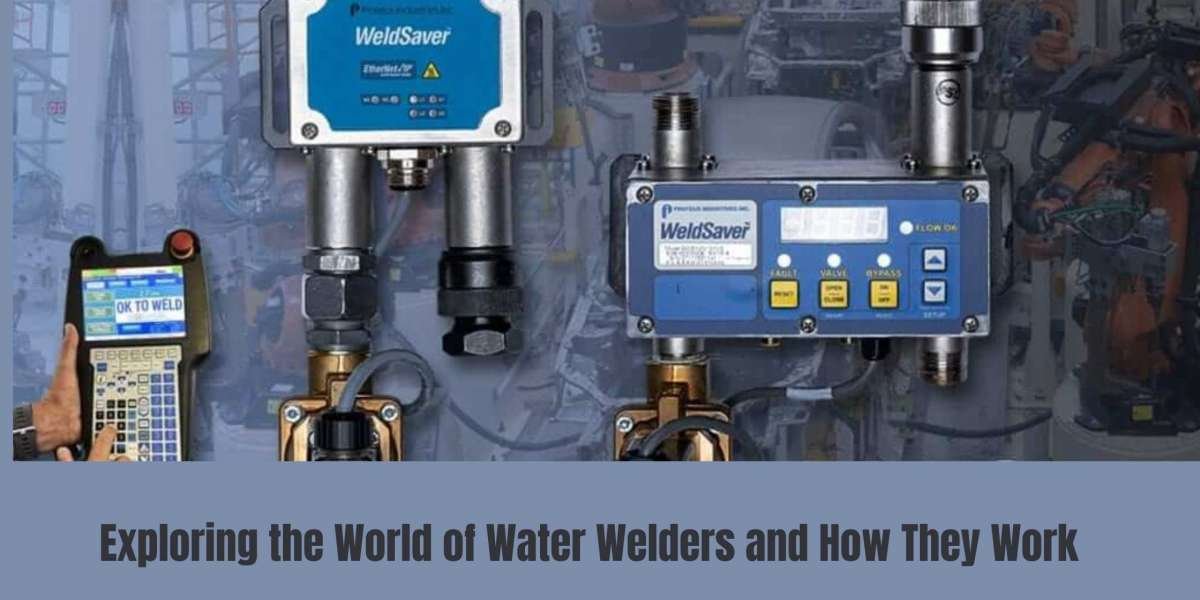

What Are Water Welders?

Water welders are welding machines that use water as a medium to help create precise and clean welds. Unlike traditional welders, which rely solely on heat, water welders utilize water as a cooling agent to minimize heat distortion and reduce the risk of burn damage to the welded materials. They are commonly used in applications that require high-quality, high-precision welding, such as in the aerospace, automotive, and manufacturing sectors.

The water used in these systems is not just there to cool the metal. It is integral to ensuring the welding process is more controlled and efficient. Water helps moderate the temperature, allowing the welder to make smooth, seamless welds without excessive heat buildup, which could cause the material to warp or weaken.

How Do Water Welders Work?

The key to understanding how water welders function is incorporating water into the cooling process. Here’s how water welders work:

- Water-Cooled Welding Methods: A water welder is typically part of a welding system that integrates water-cooled components. The basic setup includes a welding torch, a water supply, and a cooling system. The water is circulated through a closed-loop cooling system or a direct-flow setup to the welding area.

- Welding Procedure: The welding arc generates significant heat that melts the metal to create a bond. While welding is similar to traditional methods, the water around the weld area absorbs the excessive heat and prevents overheating. The cooling effect of the water allows the material to solidify quickly and uniformly.

- Temperature Management: One of the key features of water welders is their ability to provide temperature control. Traditional welding methods often lead to thermal distortion, where the heat causes the metal to deform, shrink, or expand, potentially affecting the quality of the weld. By using water, the welder can control the cooling rate and the heat-affected zone, which is crucial for high-quality welds.

- Accuracy and Cleanliness: Water acts as a cooling medium, so water welders can provide more precision during welding. The water prevents spatter, burns, or oxidation, leaving a cleaner weld that doesn’t require excessive post-welding cleanup. This helps reduce production time and overall costs.

Elements of a Water Welder

A water welder typically has several key features to provide the smooth function of the welding process. These components include:

- Welding Incendiary: The welding torch generates the heat and electrical arc needed for welding. In a water welder, the torch is connected to the cooling system, allowing water to circulate through it during welding.

- Moisture Cooling System: This is the most essential feature of a water welder. It consists of a water reservoir, a pump to circulate the water, and a cooling loop to direct the water around the welding area. The cooling system helps maintain the correct temperature for the welded materials and ensures the heat is dissipated efficiently.

- Water Flow Management: The water flow control system regulates how much water is used for cooling. By controlling the water flow, the welder can adjust the cooling rate, ensuring the correct solidification of the welded metal.

- Warmth Sink: In some water welder systems, a heat sink absorbs additional heat from the welding process and directs it to the cooling system. This helps prevent overheating and maintains the stability of the welding process.

Types of Water Welders

Water welders come in different configurations based on their specific use cases. Some of the most common types of water welders include:

- Water-Cooled Arc Welders: These welders use a water-cooled torch and cooling method to control the temperature of the weld area. They are suitable for applications requiring high precision, such as aerospace or automotive manufacturing.

- Water-Cooled TIG Welders: Tungsten Inert Gas (TIG) welders can also be configured as water-cooled systems. These welders use a water-cooled torch to provide consistent heat during welding, essential for achieving clean, smooth welds.

- Water-Cooled MIG Welders: Metal Inert Gas (MIG) welders can benefit from water cooling to reduce heat buildup. This is particularly useful in applications that need welding thin materials or long, continuous welds.

Advantages of Using Water Welders

The use of water in the welding process offers a variety of advantages over traditional welding methods. Let’s take a look at some of the key benefits:

- Improved Cooling Efficiency:One of the main benefits of water welders is the enhanced cooling efficiency. Water has a higher thermal conductivity than air, which allows it to absorb heat more effectively. As a result, the heat from the welding arc is rapidly dissipated, preventing the workpieces from overheating. This leads to a more controlled weld and reduces the likelihood of defects such as burn marks or warping.

- Concentrated Heat Distortion:Traditional welding methods often result in heat distortion due to the high temperatures generated. This can lead to warping, weakening, or cracking of the welded material. Water welders minimize heat distortion by providing consistent and controlled cooling during the weld, which helps maintain the integrity of the material and results in a stronger and more durable bond.

- More hygienic Welds:Water cooling helps to minimize oxidation and spatter, which are common problems in traditional welding. By preventing oxidation, water welders ensure the welded material remains clean and impurities-free. This reduces the need for post-welding cleanup, saving time and effort. It also results in a smoother and more aesthetically pleasing weld.

- Increased Precision:Water welders offer increased precision due to their ability to control the cooling process. With the help of water cooling, the welder can maintain the correct temperature for the material, preventing overheating and allowing for more accurate welds. This is especially important in applications where high precision is essential, such as in the aerospace and medical device industries.

- Environmental Advantages:Water welders are considered more environmentally friendly than traditional welding methods. Because water cools the system, there is less reliance on air cooling, which often requires energy-intensive fans or compressors. Additionally, water welding produces fewer harmful byproducts, such as fumes or smoke, making it a cleaner and safer option for operators and the environment.

- Energy Efficiency:Water welders are more energy-efficient than traditional air-cooled systems. The water cooling system ensures that the welding process can operate at optimal temperatures without excessive energy consumption, resulting in lower operating expenses and decreased wear and slash on the equipment.

Applications of Water Welders

Water welders are used in a variety of industries that require high-precision welding. Some typical applications include:

- Aerospace: In the aerospace industry, water welders are used to create strong, lightweight welds for aircraft parts. The precision offered by water welders ensures that critical components are securely bonded without risking damage to sensitive materials.

- Automotive: Water welders are used in the automotive industry to weld metal parts such as machine components, frames, and exhaust systems. The controlled cooling helps prevent warping and ensures the parts are strong and durable.

- Manufacturing: Water welders are used in various applications, including welding pipes, machinery components, and structural elements. The use of water cooling helps improve productivity and reduces the need for rework.

- Medical Instruments: Water welders are also used in the presentation of medical instruments that require high levels of precision. Clean welds produced by water welders are essential to providing the security and efficacy of medical supplies.

Conclusion

Water welders represent an advanced, efficient, and eco-friendly alternative to traditional welding methods. By using water as a cooling medium, they can enhance the quality of welds, reduce heat distortion, and increase precision. These systems are particularly beneficial for industries that require high-precision, clean, and durable welds, such as aerospace, automotive, and manufacturing.

Water welders offer several advantages over conventional methods, whether you want to reduce operational costs, improve welding efficiency, or minimize environmental impact. As technology advances, we expect even more applications and innovations to emerge, making water welders a key tool in modern welding processes.

FAQs

What is a water welder?

A water welder is a welding machine that uses water as a cooling medium during the welding process. It helps control the temperature, reduce heat distortion, and improve the precision and cleanliness of the weld.

How does a water welder work?

A water welder circulates water around the welding area to absorb excess heat produced during welding. The water cools the metal quickly, preventing overheating and ensuring a smooth and precise weld.

What are the advantages of using a water welder?

Water welders offer several benefits, including enhanced cooling efficiency, reduced heat distortion, cleaner welds, increased precision, and energy efficiency. They are also more environmentally friendly than traditional welding methods.

Where are water welders used?

Water welders are commonly used in industries that require high-precision welding, such as aerospace, automotive, manufacturing, and medical devices. They are ideal for applications where clean and durable welds are critical.

Are water welders more environmentally friendly?

Water welders are considered more environmentally friendly than traditional welding methods. Their efficient cooling system uses water instead of air, producing less smoke and fumes and requiring less energy.