"Gas Delivery System for Wafer Fab Equipment Market - Size, Share, Demand, Industry Trends and Opportunities

Global Gas Delivery System for Wafer Fab Equipment Market, By Bulk Gas Type (Atmospheric Gases, Hydrogen, Helium and Acetylene), Type (Semi-Automatic Switchover Systems, Fully Automatic Programmable Switchover Systems and Single Station Systems), Component (Gas Cylinders, Manifolds, Gas Cabinets, Switchovers, Protocol Stations and Changeovers), Specialty Gases Type (Ammonia (NH3), Hydrogen Chloride (HCL), Tungsten Hexafluoride (WF6), Nitrogen Trifluoride (NF3), Nitrous Oxide (N2O), Disilane (SI2H6), Germane (GEH4) and High purity Carbon Dioxide (CO2)), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel and Rest of Middle East and Africa) Industry Trends

Access Full 350 Pages PDF Report @

**Segments**

- **Product Type**: The gas delivery system for wafer fab equipment market can be segmented based on product type into cabinets, regulators, flow devices, purifiers, and other components. Each of these product types plays a crucial role in the effective operation of the gas delivery systems within wafer fabrication facilities.

- **Gas Type**: Another key segmentation for the market is based on the type of gas being delivered. This includes segmented gases such as inert gases, reactive gases, and toxic gases. The specific requirements for handling and delivering these different types of gases vary significantly, thereby driving the demand for specialized gas delivery systems.

- **End-Use Industry**: The market can also be segmented based on end-use industry, including semiconductor manufacturing, solar panel manufacturing, and other electronic component manufacturing industries. Each industry vertical has unique requirements for gas delivery systems in terms of purity, flow rate, and compatibility with specific processes.

**Market Players**

- **Linde plc**: Linde plc is a key player in the gas delivery system for wafer fab equipment market, offering a comprehensive range of products and services to meet the demanding requirements of semiconductor manufacturers.

- **Air Liquide**: Air Liquide is another prominent player in the market, known for its innovative gas delivery solutions that cater to the evolving needs of wafer fabrication facilities worldwide.

- **Matheson Tri-Gas, Inc.**: Matheson Tri-Gas, Inc. is a leading provider of specialty gases and gas handling equipment, with a strong presence in the gas delivery system market for wafer fab equipment.

- **Praxair Technology, Inc.**: Praxair Technology, Inc. offers a diverse portfolio of gas delivery systems tailored for the semiconductor industry, showcasing a commitment to quality and reliability.

- **Air Products and Chemicals, Inc.**: Air Products and Chemicals, Inc. is a global supplier of industrial gases and related equipment, including gas delivery systems designed for wafer fab equipment applicationsThe gas delivery system for wafer fab equipment market is a vital component of the semiconductor manufacturing industry, catering to the stringent requirements of delivering various types of gases to facilitate the fabrication processes. Segmentation of the market based on product type, gas type, and end-use industry allows for a more targeted approach to addressing the specific needs of semiconductor manufacturers.

In terms of product type segmentation, components such as cabinets, regulators, flow devices, purifiers, and other specialized components form the backbone of gas delivery systems within wafer fabrication facilities. Each of these product types plays a crucial role in ensuring the safe and efficient delivery of gases to the semiconductor manufacturing equipment.

Gas type segmentation is another key aspect of the market, with different gases such as inert gases, reactive gases, and toxic gases requiring specialized handling and delivery systems. The unique properties and handling requirements of each gas type drive the demand for purpose-built gas delivery solutions tailored to meet the needs of specific applications within the semiconductor manufacturing process.

End-use industry segmentation further refines the market dynamics, with semiconductor manufacturing, solar panel manufacturing, and other electronic component manufacturing industries representing distinct verticals with varying requirements for gas delivery systems. The semiconductor industry, in particular, demands high levels of purity, precise flow control, and compatibility with advanced manufacturing processes, driving the need for sophisticated gas delivery solutions.

Market players such as Linde plc, Air Liquide, Matheson Tri-Gas, Inc., Praxair Technology, Inc., and Air Products and Chemicals, Inc. are key contributors to the gas delivery system for wafer fab equipment market, offering a diverse range of products and services to meet the evolving needs of semiconductor manufacturers. These companies bring a wealth of experience, technical expertise, and innovative solutions to the market, enabling semiconductor manufacturers to enhance their operational efficiency and productivity.

In conclusion, the gas delivery system for wafer fab equipment market is characterized by a high degree of specialization, driven by the specific requirements of semiconductor manufacturing processes. Segmentation based on product**Additional Market Segments**

- **Bulk Gas Type**: The market can be further segmented based on bulk gas types such as atmospheric gases, hydrogen, helium, and acetylene. Each of these types of gases has specific handling and delivery requirements that drive the demand for specialized gas delivery systems catering to the semiconductor manufacturing industry.

- **Type of Gas Delivery Systems**: Another segmentation criterion is based on the type of gas delivery systems utilized, including semi-automatic switchover systems, fully automatic programmable switchover systems, and single station systems. The choice of system can impact operational efficiency, gas purity, and overall productivity within wafer fabrication facilities.

- **Specialty Gases Type**: The market can also be segmented based on specialty gases types such as ammonia (NH3), hydrogen chloride (HCL), tungsten hexafluoride (WF6), nitrogen trifluoride (NF3), nitrous oxide (N2O), disilane (SI2H6), germane (GEH4), and high-purity carbon dioxide (CO2). These specialty gases have unique applications in semiconductor manufacturing processes, requiring tailored delivery systems for optimal performance.

The Global Gas Delivery System for Wafer Fab Equipment Market caters to a diverse range of bulk gas types, gas delivery system types, and specialty gases types, showcasing the industry's complexity and the need for customized solutions to meet specific manufacturing requirements. The market is driven by the growing demand for semiconductor products across

Table of Contents: Gas Delivery System for Wafer Fab Equipment Market

1 Introduction

2 Global Gas Delivery System for Wafer Fab Equipment Market Segmentation

3 Executive Summary

4 Premium Insight

5 Market Overview

6 Gas Delivery System for Wafer Fab Equipment Market, by Product Type

7 Gas Delivery System for Wafer Fab Equipment Market, by Modality

8 Gas Delivery System for Wafer Fab Equipment Market, by Type

9 Gas Delivery System for Wafer Fab Equipment Market, by Mode

10 Gas Delivery System for Wafer Fab Equipment Market, by End User

12 Gas Delivery System for Wafer Fab Equipment Market, by Geography

12 Gas Delivery System for Wafer Fab Equipment Market, Company Landscape

13 Swot Analysis

14 Company Profiles

Countries Studied:

- North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

- Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

- Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

- Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Objectives of the Report

- To carefully analyze and forecast the size of the Gas Delivery System for Wafer Fab Equipment market by value and volume.

- To estimate the market shares of major segments of the Gas Delivery System for Wafer Fab Equipment

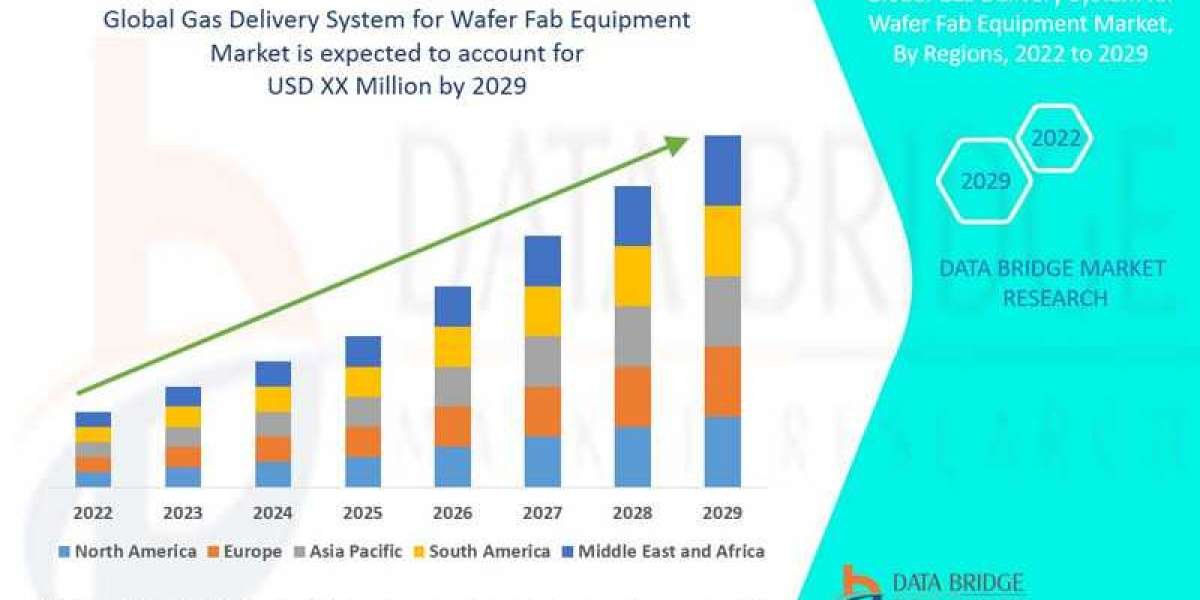

- To showcase the development of the Gas Delivery System for Wafer Fab Equipment market in different parts of the world.

- To analyze and study micro-markets in terms of their contributions to the Gas Delivery System for Wafer Fab Equipment market, their prospects, and individual growth trends.

- To offer precise and useful details about factors affecting the growth of the Gas Delivery System for Wafer Fab Equipment

- To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Gas Delivery System for Wafer Fab Equipment market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Browse Trending Reports:

On Premise Content Intelligence Market

Polyolefin Catalyst Market

Cold Pressed Sesame Seed Oil Market

Alstorm Syndrome Treatment Market

Bio Polybutylene Succinate Coatings Market

Microneedling Market

Cervical Retractors Market

Vascular Closure Device Market

Veterinary Reference Laboratory Market

Polypropylene Catalyst Market

Temperature Controlled Primary Packaging Solutions Market

Indoor Robots Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975