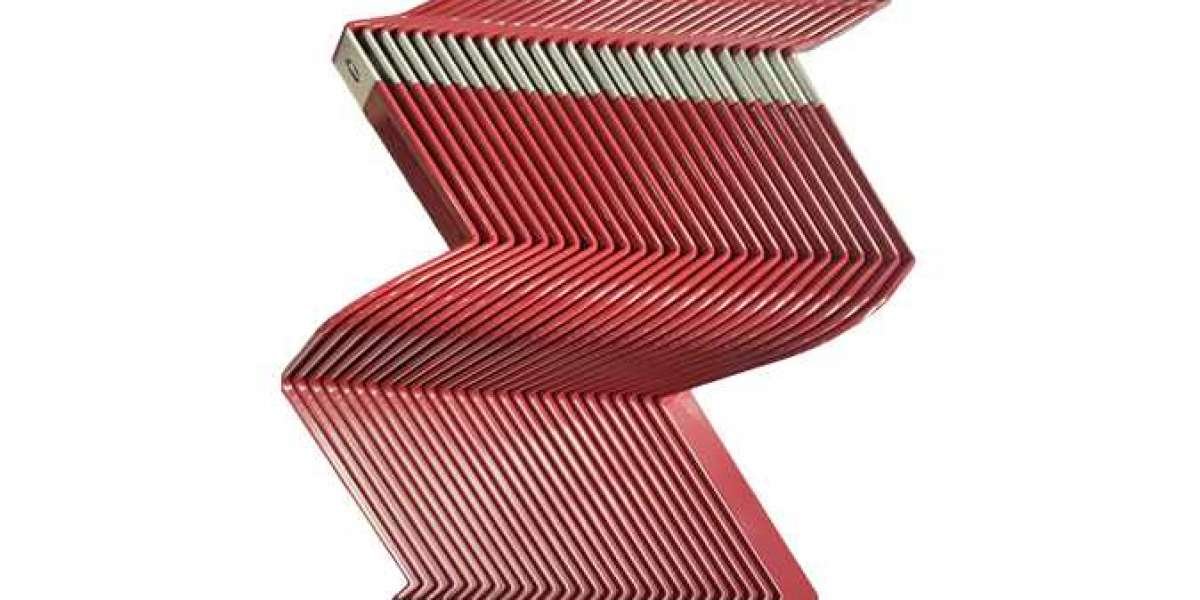

, Among the exciting things about renewable energy is: inverters are pretty neat. They convert the direct current (DC) generated by solar panels or wind turbines into alternating current (AC). This AC electricity is then distributed to homes, businesses, and communities. A key component in these inverters is the copper shunt. The copper shunt regulates the flow of electricity and prevents things from becoming too hot. But over time the copper shunt can be damaged by thermal stress and may no longer work as well or as long.

Examining How Copper Shunts Perform in Various Temperatures

Scientists and engineers at Kinto are examining how heat affects copper shunts in renewable energy inverters and are conducting experiments on laminated copper shunts across various temperatures. They test these shunts in very hot and cold environments. By examining how they survive and conduct electricity, scientists can get a sense of how different conditions might upend their performance.

Enhancing the Design of Copper Shunt to Enhance the Thermal Stress

One design idea is that Kinto's experts have discovered during the investigation is some design to mitigate thermal stress of the copper shunts for renewable energy inverter. Engineers can create shunts that can endure temperature shifts and are less prone to being damaged, using new materials and better manufacturing processes. These enhanced inverter designs don’t just help the inverters perform better and last longer, but they are also helping build a more sustainable energy future.

Investigation on Copper Shunts and the Reasons for Its Temperature Dependence

Kinto’s research and development team is constantly studying laminated copper shunts and how they work in practical usage. They examine the action of these shunts over time to learn how thermal stress impacts their reliability and lifespan. This kind of research is extremely important lighting busbar to ensure that renewable energy systems function and are cost-effective over the long term.

Significance of Thermal Stress in Copper Shunts

The investigation of thermal stress for copper shunt in inverters is very essential based on the results obtained by Kinto. By understanding these key parts and how thermal stress impacts their performance, engineers 300 amp busbar can design a more robust, durable inverter that can withstand daily use as well as the harshest of rain, wind, and snow. This research contributes to the development of renewable energy technology and a more sustainable and energy abundant future.

Finally, investigating the thermal stress in fully laminated copper shunts for renewable energy inverters is highly significant. It may help keep these parts functioning better and longer. Researchers at Kinto are thus also contributing to research for innovation in braided busbar renewable energy field by understanding the effect of thermal stress on copper shunts, looking for design ideas to minimize its impact, and verifying their stability”. Their effort is a gift of greenness and sustainability to future generations.