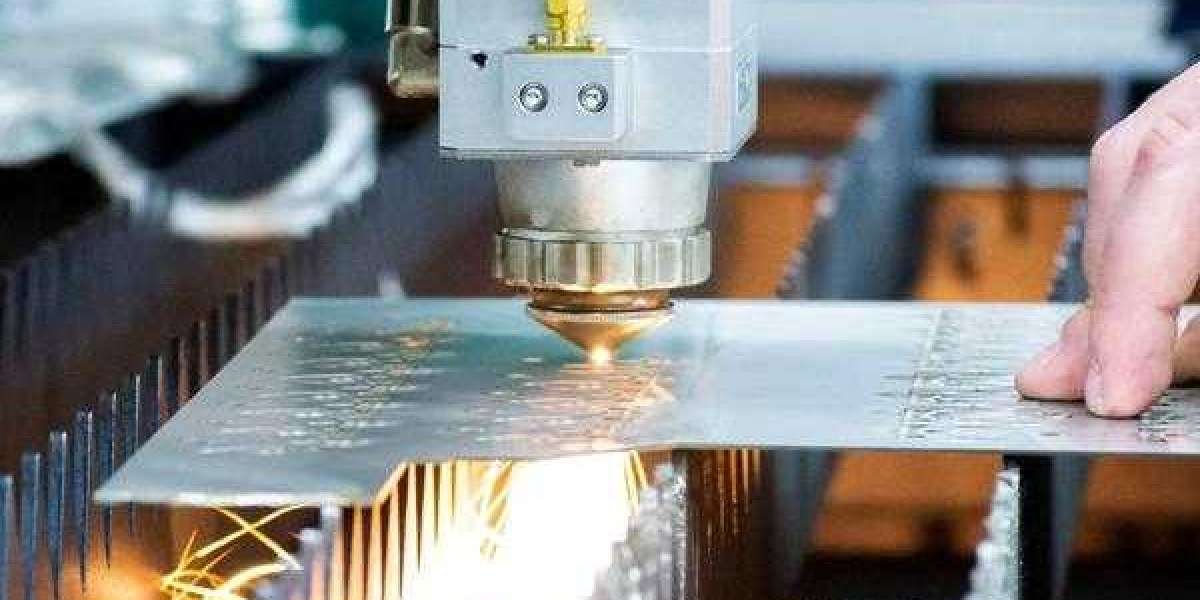

Looking to remove rust, paint, grease, or contaminants from metal, stone, or delicate surfaces? A laser cleaning machine for sale might be exactly what your operation needs. These machines are redefining how industries handle surface preparation, offering a non-contact, eco-friendly solution that delivers remarkable results without damaging the base material.

In this comprehensive guide, we’ll explore everything you need to know about laser cleaning systems—from core features to buying tips—built around the latest SEO and EEAT standards to help you make informed, trusted decisions.

What is a Laser Cleaning Machine?

A laser cleaning machine uses a high-intensity laser beam to remove unwanted substances from surfaces. This process, often called laser ablation, is fast becoming a popular alternative to traditional methods like sandblasting, chemical cleaning, and manual scrubbing.

Unlike abrasive methods, laser cleaning is:

Non-destructive

Environmentally friendly

Low maintenance

Highly precise

It’s used across various sectors—automotive, aerospace, restoration, mold cleaning, military, and manufacturing—to extend equipment life, reduce downtime, and improve quality control.

Types of Laser Cleaning Machines

| Type | Power Range | Typical Application |

|---|---|---|

| Low-Power (20W–100W) | Compact portable | Restoration, artifact cleaning |

| Mid-Power (100W–200W) | Industrial tasks | Paint, coating, adhesive removal |

| High-Power (200W–2000W+) | Heavy-duty use | Large-scale rust oxide removal |

Key Features to Look For

When searching for a laser cleaning machine for sale, prioritize the following:

Fiber Laser Source: Known for stability and long service life (up to 100,000 hours)

Adjustable Power Settings: Enables flexibility for various materials

Air Cooling or Water Cooling: Important for longer continuous operations

User-Friendly Interface: Touchscreens, presets, and safety controls enhance usability

Portable or Handheld Options: Ideal for on-site jobs or hard-to-reach areas

Benefits of Investing in Laser Cleaning Technology

No Consumables: Eliminates the need for chemicals, abrasives, or solvents

High Precision: Selectively targets contaminants without surface damage

Low Operational Cost: Minimal maintenance and energy-efficient

Safe for Operators: Enclosed beam path and safety sensors reduce risk

Environmentally Sustainable: No secondary waste, supports green manufacturing

How Much Does a Laser Cleaning Machine Cost?

| Power Level | Estimated Price Range (USD) |

|---|---|

| 50W–100W | $3,000 – $8,000 |

| 100W–200W | $8,000 – $18,000 |

| 200W–1000W+ | $18,000 – $60,000+ |

Prices can vary depending on brand, cooling system, software features, and portability. Always consider warranty and support packages.

Applications Across Industries

Automotive: Engine parts, chassis rust removal, weld prep

Shipbuilding: Removing marine biofouling, paint stripping

Aerospace: Cleaning turbine blades and molds

Cultural Restoration: Safe removal of pollutants on monuments or artifacts

Electronics: Precision cleaning of solder joints and micro components

Frequently Asked Questions (FAQs)

Q1: Can a laser cleaning machine damage the surface?

A: Not if used correctly. Laser systems can be finely tuned to target only contaminants without affecting the underlying material.

Q2: Is laser cleaning better than sandblasting?

A: Yes, for precision jobs. Laser cleaning is non-abrasive, cleaner, and safer, though sandblasting may still be used for heavy industrial tasks with lower precision needs.

Q3: What maintenance does a laser cleaner require?

A: Very little. Just regular lens cleaning and occasional software updates. Fiber lasers are known for their longevity and low failure rates.

Q4: How fast does it clean?

A: Cleaning speeds vary by power and material. A 1000W machine can clean rust from a steel plate at over 15 m²/hour.

Q5: Do I need special training to operate it?

A: Most machines come with user-friendly interfaces. Basic safety and operation training is usually sufficient.

Tips for Choosing the Right Laser Cleaning Machine

Match the power level to your task size and frequency

Check for CE/FDA certifications for safety

Ask for a demo or video samples before buying

Ensure after-sales support and parts availability

Read verified reviews or case studies from similar industries

Final Thought

Choosing the right laser cleaning machine for sale isn’t just about specs—it’s about maximizing efficiency, reducing waste, and improving operational safety. Whether you're a manufacturer, restorer, or industrial contractor, laser cleaning is a future-ready investment.