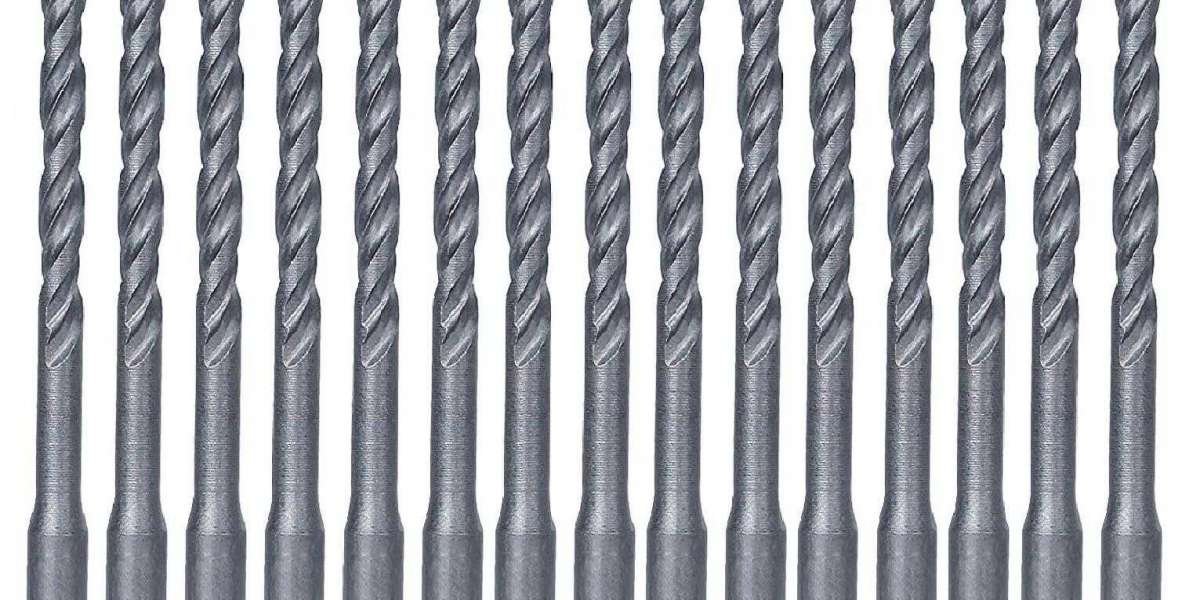

On construction sites and in renovation projects, drilling performance can directly influence work pace and precision. The SDS Drill Bit from Fangda brings dependable energy transfer and efficiency to tasks involving dense substrates, particularly in concrete, stone, and brick.

This type of bit is designed with a specific shank system that secures it firmly inside rotary hammer drills. The configuration allows quick changes without additional tools, streamlining movement between drilling steps. Its unique shape ensures power moves directly into the surface, not wasted through slippage or misalignment.

Durability is a core concern when working in high-pressure environments. The drill bit’s composition resists distortion and retains sharpness over repeated use. Advanced heat treatment methods applied during production improve its surface hardness, helping the tip cut through surfaces while resisting cracks and chips.

Drilling efficiency also depends on how well debris is cleared. Flute geometry helps remove dust and fragments from the hole path, maintaining consistent depth without stalls. This contributes to a cleaner result and simplifies anchor placement and wall installations.

Comfort is important too. Design refinements focus on balance and vibration reduction, allowing users to maintain accuracy without fatigue. This becomes increasingly important in longer shifts or where alignment is key to joint or fixture performance.

The tool’s versatility makes it suitable for residential fitting tasks, industrial retrofits, and structural installation. Contractors can shift from block wall tasks to foundation works with minimal adjustment.

In modern construction workflows, time and tool longevity directly affect jobsite efficiency. Choosing components that can handle repeated drilling under stress not only protects workers but also supports cleaner, more reliable results.

For drill bits that deliver consistent action in demanding conditions, visit: www.fangda-tools.com