In today's fast-paced industrial landscape, the demand for efficient and effective repair solutions has never been higher. Portable laser welding machines have emerged as a revolutionary tool in on-site repairs, offering unmatched precision and versatility. This article explores the significant role these machines play in various industries, their advantages over traditional welding methods, and how they cater to the specific needs of international customers.

Understanding Portable Laser Welding Machines

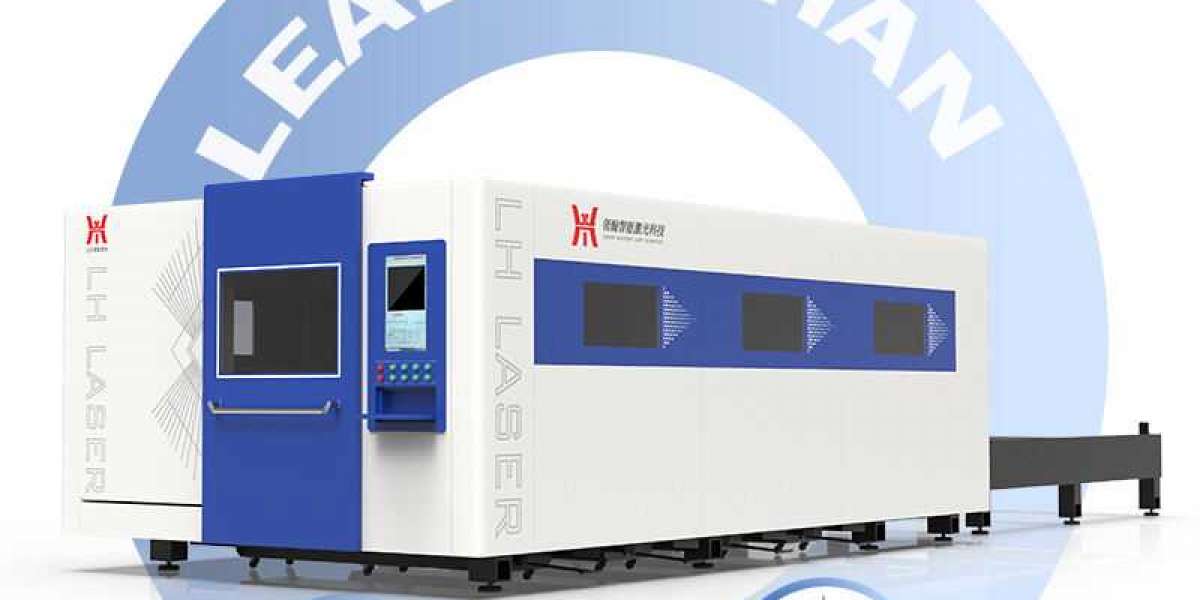

Portable laser welding machines utilize high-intensity laser beams to melt and fuse materials together. Unlike conventional welding techniques, which often require extensive setup and can be cumbersome, portable laser welding allows for quick and efficient repairs directly at the job site. This mobility is crucial for industries such as automotive, aerospace, and manufacturing, where downtime can lead to significant financial losses.

Advantages of Portable Laser Welding

One of the primary benefits of portable laser welding machines is their precision. The focused nature of laser beams allows for minimal heat-affected zones, reducing the risk of warping or damaging surrounding materials. This precision is particularly advantageous when working with delicate components or when repairs must be made in tight spaces. Furthermore, the speed of laser welding significantly reduces the time required for repairs, enhancing overall productivity.

Versatility Across Industries

Portable laser welding machines are not limited to a single application. They can be used for a variety of materials, including metals, plastics, and even ceramics. This versatility makes them an ideal choice for diverse industries such as construction, shipbuilding, and electronics. For instance, in the automotive sector, these machines can efficiently repair exhaust systems, while in aerospace, they can be used for intricate repairs on aircraft components.

Cost-Effectiveness and Sustainability

Investing in portable laser welding technology can lead to substantial cost savings in the long run. The efficiency of laser welding not only reduces labor costs but also minimizes the need for additional materials due to its precision. Moreover, as industries increasingly focus on sustainability, laser welding offers an eco-friendly alternative by producing less waste and requiring lower energy consumption compared to traditional welding methods.

Future Trends in Portable Laser Welding

As technology continues to advance, the future of portable laser welding looks promising. Innovations such as automation and integration with artificial intelligence are expected to enhance the capabilities of these machines further. Additionally, the growing trend towards remote work and decentralized manufacturing will likely increase the demand for portable solutions, making laser welding a vital component of on-site repairs.

In conclusion, portable laser welding machines are transforming the landscape of on-site repairs, offering unparalleled precision, efficiency, and versatility. As industries continue to evolve, these machines will play a crucial role in meeting the demands of modern repair needs, making them an invaluable asset for businesses worldwide.